A tripartite partnership between Japanese shipping companies has achieved a 93.8% reduction in methane exhaust from a marine gas engine operating at 100% load in onshore tests, paving the way for trials at sea.

11 Apr 2024

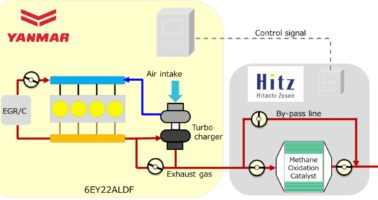

The research results, which were verified by ClassNK through a statement of fact (SOF), were achieved on a test engine using an exhaust gas recirculation (EGR) system. in English) in combination with a methane oxidation catalyst system. Although results were achieved on the testbed in December 2023, ClassNK unveiled the SOF at a ceremony held at Sea Japan 2024 in April.

These results are encouraging for the use of liquefied natural gas (LNG) dual-fuel engine technology in ships to achieve reductions in CO2 and greenhouse gas (GHG) emissions.

Supported by Japan's National Institute of New Energy and Industrial Technology Development (NEDO), the ongoing research is being carried out by Hitachi Zosen Corp, Mitsui OSK Lines (MOL) and Yanmar Power Technology under the Methane Exhaust Reduction Technology Development Project from LNG-Powered Vessels by Improving Catalysts and Engines, under the Green Innovation Funds Program. The project that runs from 2021 to 2026, aims to achieve a 70% reduction in methane leakage from LNG-powered vessels.

Depending on the type of engine technology, LNG combustion can reduce CO2 emissions from combustion by 20% to 25%, particulate matter and sulfur oxides by approximately 100%, and nitrogen oxides by approximately 80%. Methane leak is a problem for dual-fuel LNG engines, especially two- and four-stroke engines based on the Otto cycle. Methane is a powerful greenhouse gas, with a global warming potential 27-30 times that of CO2 over 100 years, according to the U.S. EPA. Natural gas, used in propelled engines by LNG, is composed mainly of methane. Exhaust methane is the unburned natural gas that escapes from the ship's exhaust during combustion. This undermines the environmental benefits of using LNG as a marine fuel.

The European FUEL EU regulations establish the following default methane leak values, although shipowners may use their own values if they are certified by a classification society.

| Type of motor | % methane slip | |

| LNG Otto (dual fuel medium speed) | 3,1 | |

| LNG Otto (dual fuel slow speed) | 1,7 | |

| LNG Diesel (dual fuel slow speed) | 0,2 |

In 2022, ClassNK issued an in-principle approval for the methane oxidation catalyst system concept designed by Hitachi Zosen and Yanmar PT. The device is designed to reduce methane leakage by placing a methane oxidation catalyst in the exhaust pipe of an LNG-powered engine and oxidizing unburned methane in the catalyst.

Based on the test procedure submitted by Yanmar PT, ClassNK issued a SOF after confirming the reduction of methane exhaust under LNG combustion conditions from marine dual-fuel engines equipped with a methane exhaust reduction system.

Next step: trials at sea

Starting in the fourth quarter of 2024, the methane leak reduction technology will be installed on the Reimei bulk carrier, launched in 2023 and equipped with dual LNG engines, to demonstrate the technology during sea trials. Managed by MOL and owned by Erica Navigation, the 95,792 dwt Liberian-flagged bulk carrier was delivered in November to transport coal for Kyushu Electric Power. Plans call for the methane oxidation catalyst system to be installed on the Yanmar 6EY22ALDF engine technology

.