Wärtsilä Corporation, Press release 8 October 2020 at 10:00 AM E. Europe Standard Time

The Wärtsilä technology group has won a major contract to supply and build a CO2-neutral liquid transport fuel production plant. The plant will liquefy gas from the natural gas network to produce carbon neutral LNG. It will have a capacity of approximately 100,000 tons per year and will be located in Cologne, Germany. The order from Wärtsilä was placed in September 2020.

Wärtsilä's vast experience and state-of-the-art technologies developed for process design, manufacturing and delivery of gas liquefaction plants and mature gas treatment solutions prior to liquefaction were key factors in securing the contract.

"We are honored to have received this order for a landmark project. We take this as a clear endorsement of Wärtsilä's capabilities in this field. The use of LNG as an emissions-reducing fuel in the marine and transportation industries is already well established, and "The introduction of bio LNG that can be blended with LNG is the obvious next step to enable a CO2-neutral transportation fuel. We look forward to continuing our mission of enabling sustainable societies with smart technology."

Antti Kuokkanen, Vice President of Gas Solutions.

The raw material for bioLNG is based on biological waste material, for example liquid manure and food waste. The raw material is fed to an anaerobic digestion reactor that produces biogas, which is then converted into biomethane and injected into the natural gas network. Green gas certificates are issued alongside the injected biomethane, allowing operators elsewhere, such as liquefaction plants that produce bioLNG, to purchase the certificates and use the biomethane.

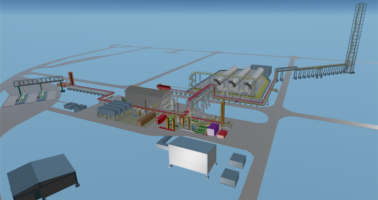

Wärtsilä's scope for this project includes engineering, civil works, installation and commissioning of the plant. The plant will include a gas treatment system based on Wärtsilä's Puregas CA technology, a liquefaction unit using Wärtsilä's Semi-Dual Brayton technology, storage tanks, truck filling stations and all auxiliary and flare equipment. security required. The plant is expected to be fully operational in the fall of 2022.

Gas Solutions is a market leader with innovative systems and life cycle solutions for the gas value chain. Our main areas of interest are gas handling in maritime transport (storage, fuel, transfer and BOG management), gas to electricity, liquefaction and biogas solutions. We help our clients on the path to a sustainable future by focusing on lifecycle, innovation and digitization.